Our Projects

Bridge Repair

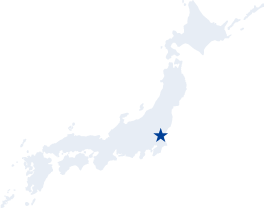

(Seismic Reinforcement of

Karisaka-Ohashi Bridge)

Saitama

Client: Local government

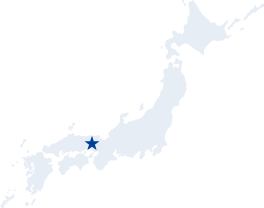

Kozakai Overpass Superstructure Work Phase 2, Onramps

Aichi

Client: Local government

We installed bridge girders in Kozakai Overpass on National Highway 247 in Toyokawa City, Aichi Prefecture, in order to widen the overpass to alleviate congestion where the national highways intersect. We installed 17 main girders, each with a length of 25 meters. Unlike new construction, this work required high levels of precision as the new girders had to be integrated into the existing overpass, but through thorough construction management, the project was completed with no accidents or incidents, and received high praise from the client.(2024)

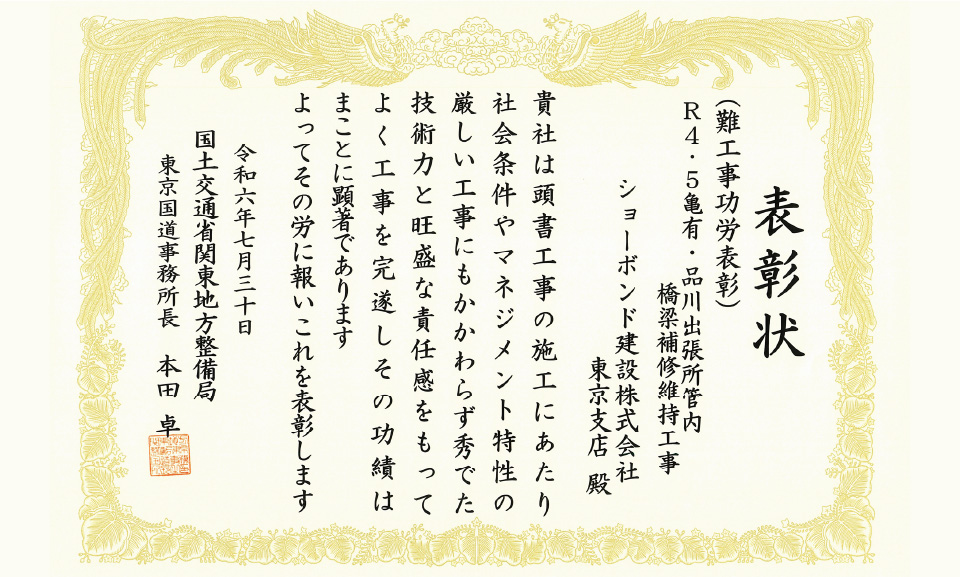

R4/5 Bridge Repair

and Maintenance Works of Kameari

and Shinagawa Branch Office Areas

Tokyo

Client: MLIT (National government)

We completed repair works for four pedestrian bridges, including Shintokai-bashi Pedestrian Bridge and Ryogoku Bridge, as well as three other bridges that are integral to the local community (the photo shows Shintokai-bashi Pedestrian Bridge after repainting and waterproofing coating). Due to the nature of working on multiple sites, complex process management and safety controls were required. However, through close and ongoing consultations with the client, we completed the project safely, with no accidents or incidents, and received a commendation for excellent work from the Director of the Tokyo National Highway Office.(2024)

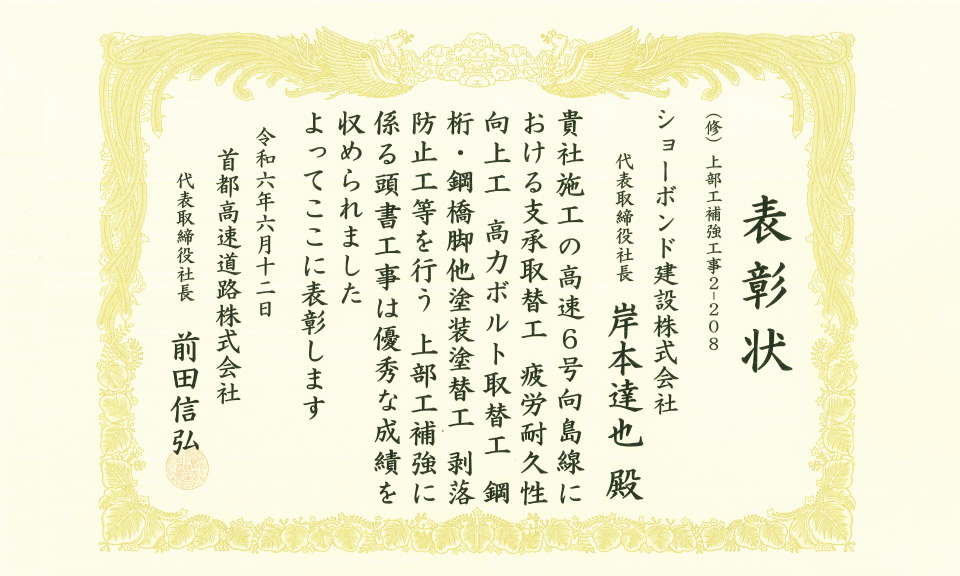

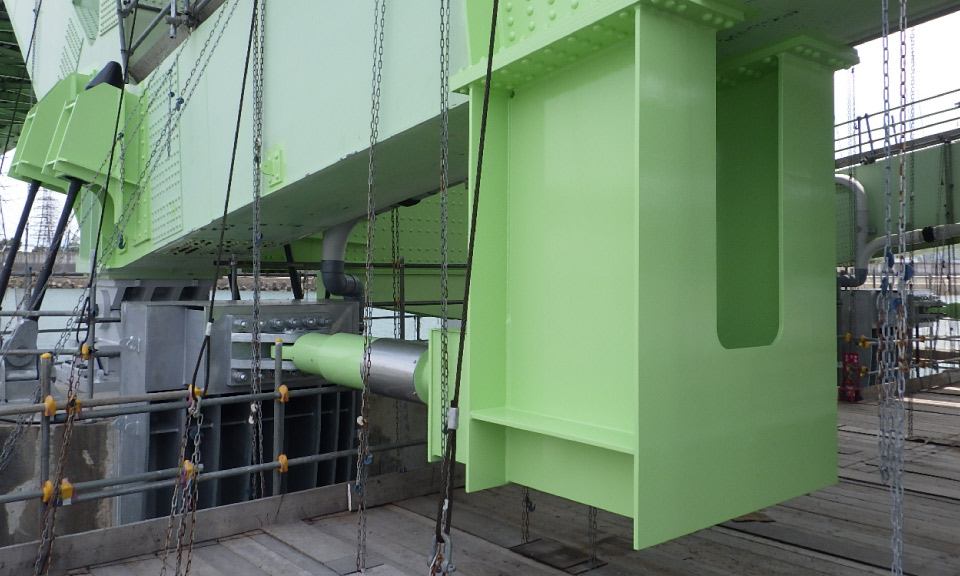

(Revised) Reinforcement

of Superstructure 2-208

Tokyo

Client: Expressway company

On the Metropolitan Expressway Route No. 6 Mukojima Line, we carried out a large-scale bridge repair project spanning approximately seven years, covering a distance of 950 meters and 23 spans. The work included deck slab reinforcement, bearing replacement, and repainting. Despite the urban-specific challenges, such as working above the Sumida River, on metropolitan roads, and at Ryogoku Junction and park areas, we completed the project without any accidents or incidents. In recognition of this, we received commendations for excellent work and outstanding safety management from Metropolitan Expressway Co., Ltd.(2024)

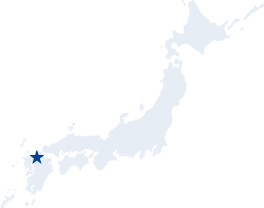

Port Facility Improvement

(Earthquake-Proofing) Construction

Project at Wakayama Shimotsu Port

Wakayama

Client: Local government

Moon Bridge connects the city area of Kainan-city to “Wakayama Marina City,” a leisure resort situated on an artificial island. The earthquake-proofing work involved the installation of seismic damper, PC cable, and steel brackets. The work, which included off-shore work was carried out in harsh environmental conditions with fierce wind and rain. Nevertheless, the project was completed with no accidents or incidents, and received high praise from the client.(2023)

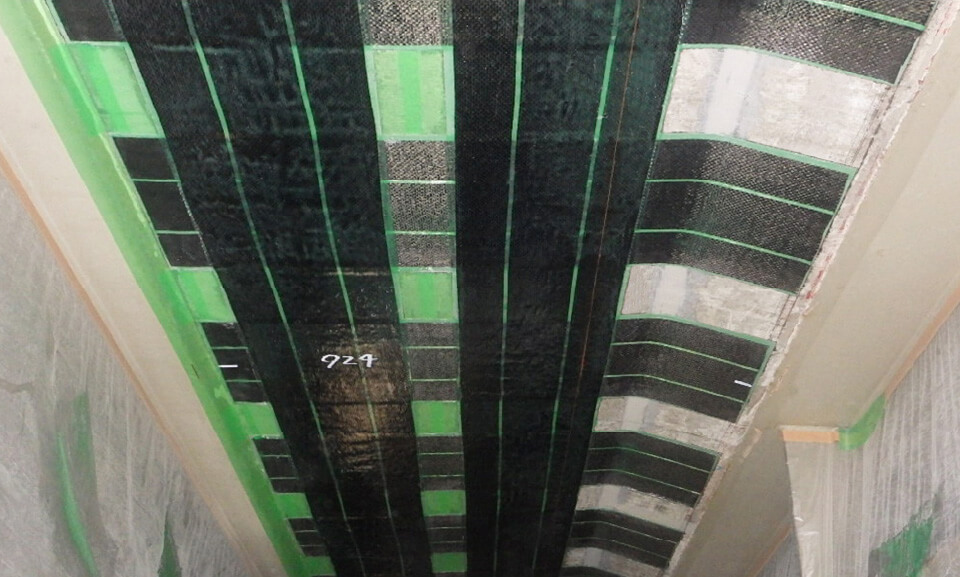

R4 Repair Work on Kawada Viaduct

of National Highway 50

Ibaraki

Client: MLIT (National government)

At seven sites including the Kawada Viaduct and the Kasama Overbridge on National Highway 50 in Ibaraki Prefecture, various kinds of roadwork construction were conducted (photo shows the reinforcement of deck slabs with carbon fiber sheets at the Kasama Overbridge). As roadwork was underway at multiple sites simultaneously, managing the complex processes was very challenging. Despite this, we successfully completed the project within the allotted timeframe, without any accidents or incidents. We employed innovative techniques like 3D scanning and received commendation from the client.(2023)

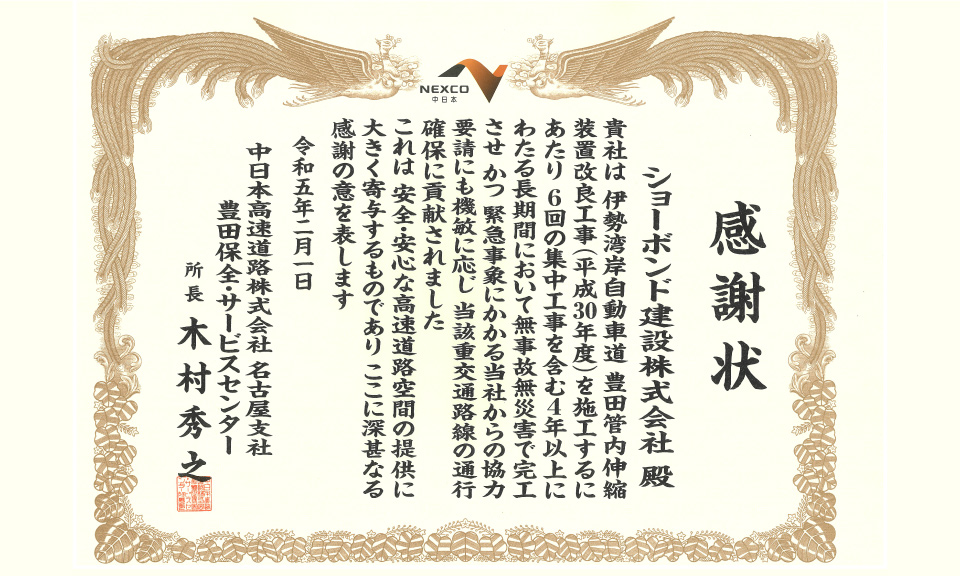

Expansion joint improvement work

in the Toyota area of

Isewangan Expressway (fiscal year 2018)

Aichi

Client: Expressway company

On the viaduct between Isewangan Expressway’s Toyota-higashi Interchange and Tobishima Interchange, we engaged in six rounds of centralized work over a period of approximately four years in carrying out replacement of 23 expansion joints with the aim of enhancing fatigue durability. Although the work was continuous day and night with lane restrictions on the expressway, we successfully completed the work without accidents or mishaps by responding flexibly to the changes from day to day. We accordingly received a certificate of appreciation from Central Nippon Expressway Company Limited for these efforts.(2023)

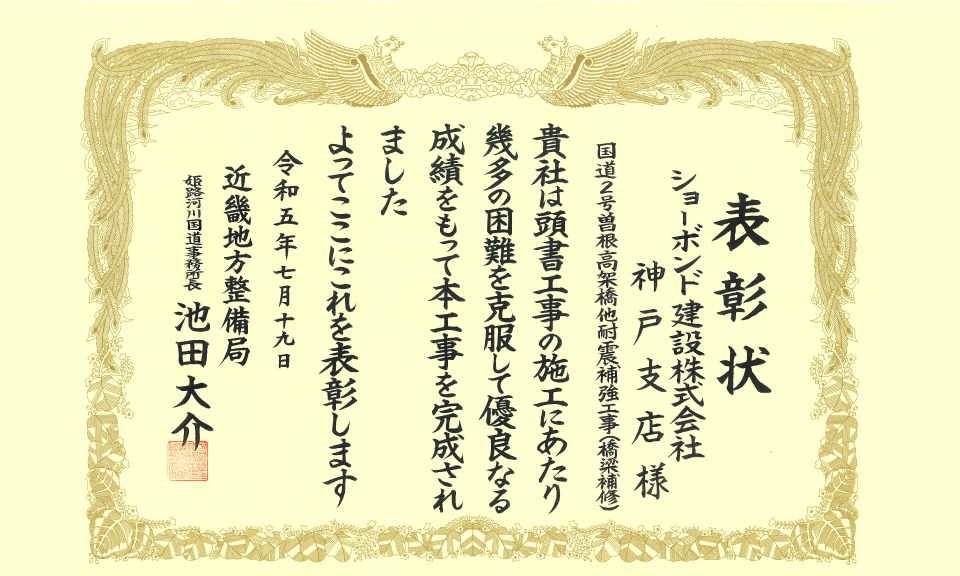

Seismic retrofitting work

of Sone Viaduct, etc.

of National Highway 2 (bridge repair)

Hyogo

Client: MLIT (National government)

The Sone Viaduct is an elevated bridge on Himeji Bypass of National Highway 2 crossing the Harima coastal area. The work mainly involved installation of horizontal force allocation structure to improve seismic resistance. Whereas the project called for particularly stringent safety controls given that construction took place above National Highway 250 as it remained in operation, we successfully completed the project without any accidents or mishaps and accordingly received commendation for excellent work from the Director of the Himeji Office of River and National Highway affiliated with the Kinki Regional Development Bureau of the Ministry of Land, Infrastructure, Transport and Tourism.(2023)

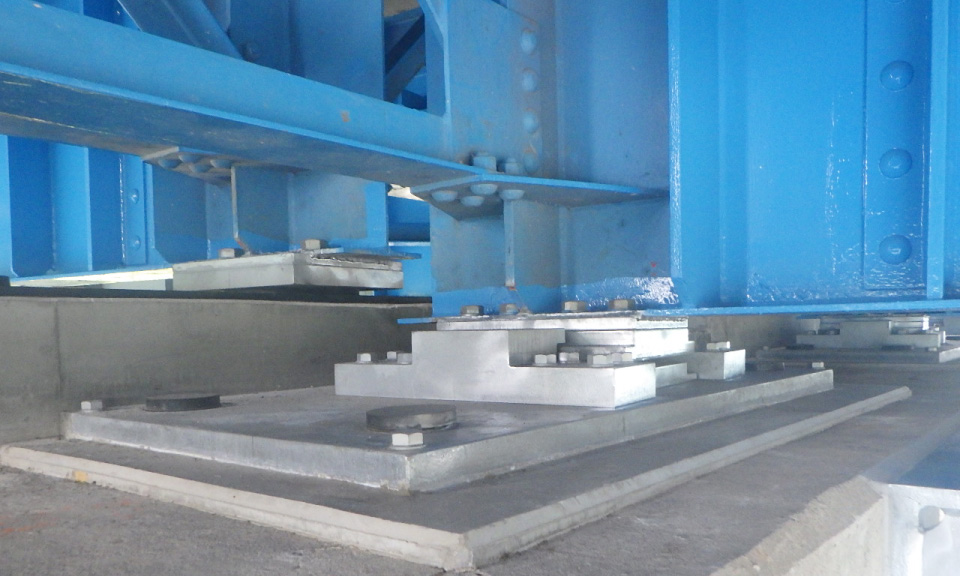

Kinegawa Bridge Viaduct Repair Work

(Bearing Reinforcement) (Phase 2)

Tokyo

Client: Local government

The Kinegawa Bridge Viaduct is a bridge connected to the Kinegawa Bridge spanning Arakawa, a class A river. As part of seismic work, we replaced the bearing, reinforced bridge piers, and installed bridge falling prevention devices. Although this work was carried out under difficult conditions in a river area where excavation around the bridge piers was performed during the dry season and many processes involved using heavy machinery in the narrow space below the girders, we were able to complete the project without accidents or mishaps, and received high praise from the client.(2022)

Tatara River Bridge

Repair Work (31-2)

Fukuoka

Client: Expressway company

On the viaduct between the Najima ramp entry/exit and the Kaizuka junction, we carried out the reinforcement of deck slabs with carbon fiber, repainting of steel girders, and concrete spalling prevention with bridge piers and concrete bridge barriers as deterioration measures and preventive maintenance. Although this work was carried out under difficult conditions involving repeated scaffolding assembly and disassembly at night, we were able to complete the project on schedule within approximately three years, without any accidents or mishaps, and received high praise from the client.(2022)

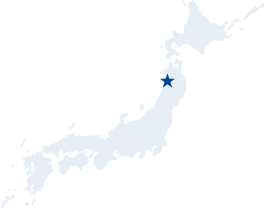

Reconstruction/Renovation of

Towada Jurisdiction Expressway

on Tohoku Expressway

Akita

Client: Expressway company

The Group received an order by a joint venture for renewal project construction for a highway where bridge deck slab exchange and tunnel repair are carried out simultaneously. The Company was in charge of repair work for 22 tunnels interspersed over 66 km, and carried out bonding of carbon fiber lining, void filling for the back surface of lining, etc. The Company completed three years of construction without any accidents or mishaps, and received the Commendation for Excellent Construction by East Nippon Expressway Company Limited.(2022)

Seismic retrofitting work of

Kanagawa Branch Office area

Kanagawa

Client: MLIT (National government)

The Group carried out seismic retrofitting work for Asahi Kokakyo, viaduct, which spans National Highway 15, part of the course for the Hakone Ekiden.

Although construction was carried out under difficult conditions while using parking lot under the viaduct, the fact that the Group completed construction without any accidents or mishaps due to the proposal of a construction method that minimizes the impact to users was rated highly, and received the Director-General’s Commendation for Excellent Construction and Excellent Construction Engineers from the Kanto Regional Development Bureau of the Ministry of Land, Infrastructure, Transport and Tourism.(2022)

Repair work of Oi-Hokubu Overpass

(phase 4) and maintenance work of

Oi-Hokubu Overpass (bridge pavement)

Tokyo

Client: Local government

The Oi-Hokubu Overpass in Shinagawa-ku, Tokyo, is an overpass comprised of four ramp bridges. Construction of this overpass was completed in 1973, ahead of the opening of the Oi Container Terminal. Because aging of the deck slabs had progressed due to the extremely large traffic volume of large vehicles, construction was carried out to remove all the existing deck slabs and install new deck slabs. Although construction was carried out while the overpass was closed to traffic around the clock, we were able to complete the construction prior to the Tokyo Olympic Games without any accidents or mishaps, and received high praise from the client. (2021)

Reinforcement work of Karasuyama

Viaduct on Chuo Expressway

Tokyo

Client: Expressway company

The Karasuyama Viaduct is a bridge located between the Takaido Interchange and the Chofu Interchange of the Chuo Expressway. The main construction work was linking concrete girders using external cables and eliminating expansion joints above the bridge piers in order to construct a structure to prevent the bridge from falling during an earthquake. Because there were residential areas near the construction zone, which was approximately 1 km long, we implemented noise control and other measures in consideration of those living in the surrounding area. In addition, although the construction required a long period of four and a half years, we completed the construction safely and successfully, and received high praise from the client.(2021)

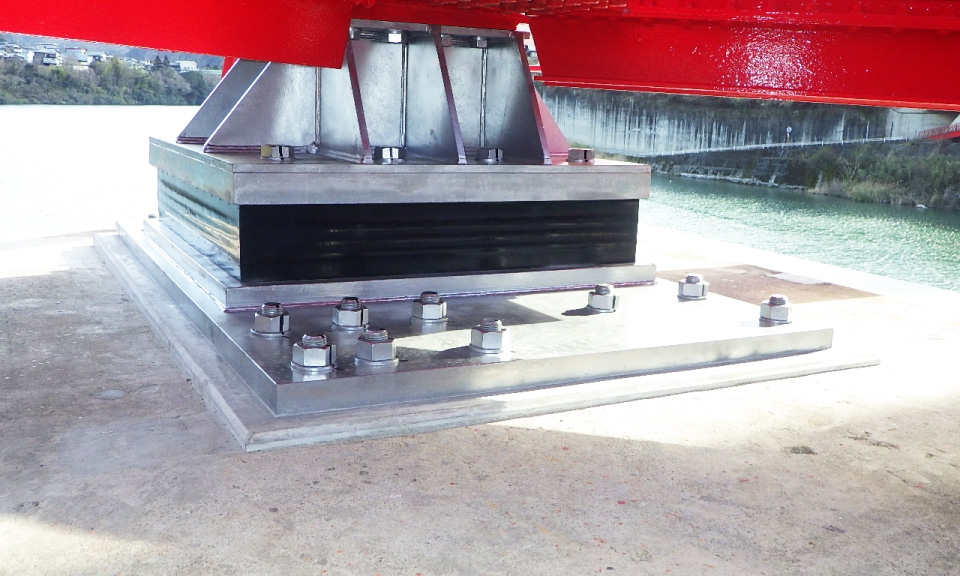

The Ikeda-ohashi Bridge

Tokushima

Client: MLIT (National government)

The Ikeda-ohashi Bridge is a 294-meter-long bridge spanning the Yoshino River in Miyoshi City, Tokushima Prefecture. In this project, bearings were replaced in the central truss to improve earthquake resistance. The project received an award from Director of Tokushima Office of Rivers and National Highways of the MLIT’s Shikoku Regional Development Bureau for its safety-conscious construction work, which included the installation of temporary girders that were not part of the original plan to replace bearings with a total weight of approximately six tons.(2021)

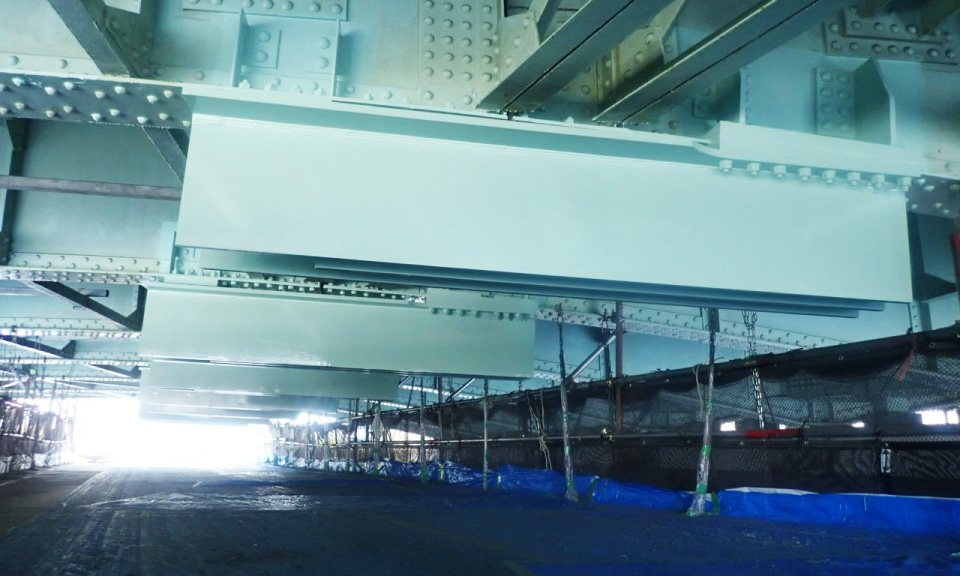

Yotsuike Viaduct and others on

National Highway 26

Osaka

Client: MLIT (National government)

In addition to the seismic reinforcement work for bearing reinforcement structures, etc., for two bridges over National Highway 26, one more difficult bridge repair work with a demanding process was added. Although three bridges were to be constructed simultaneously, the Osaka National Highway Office of the MLIT’s Kinki Regional Development Bureau highly praised the project for its smooth process management, including measures to deal with neighboring residents and coordination with other construction projects in the vicinity, and we were awarded the Bureau Director’s Commendation for Excellent Construction.(2021)

Hamacho Station

(Metropolitan Subway)

Tokyo

Client: Railway company

Hamacho Station is a subway station on the Toei Shinjuku Line in Chuo Ward operated by the Tokyo Metropolitan Bureau of Transportation. It opened on December 21, 1978, meaning it will have been in operation for 43 years by the end of 2021. Since the construction was done on the subway premises while it was in operation, work had to be performed within the limited time from 24:35 after the last train departed to 3:30 in the morning, before the first train arrived. The project included the renewal of elevators and escalators, and we paid close attention to details such as notifying general users of downtime due to construction, and other matters such as security guard deployment, training and communications. Thanks to these fforts, the work was completed safely and successfully.(2020)

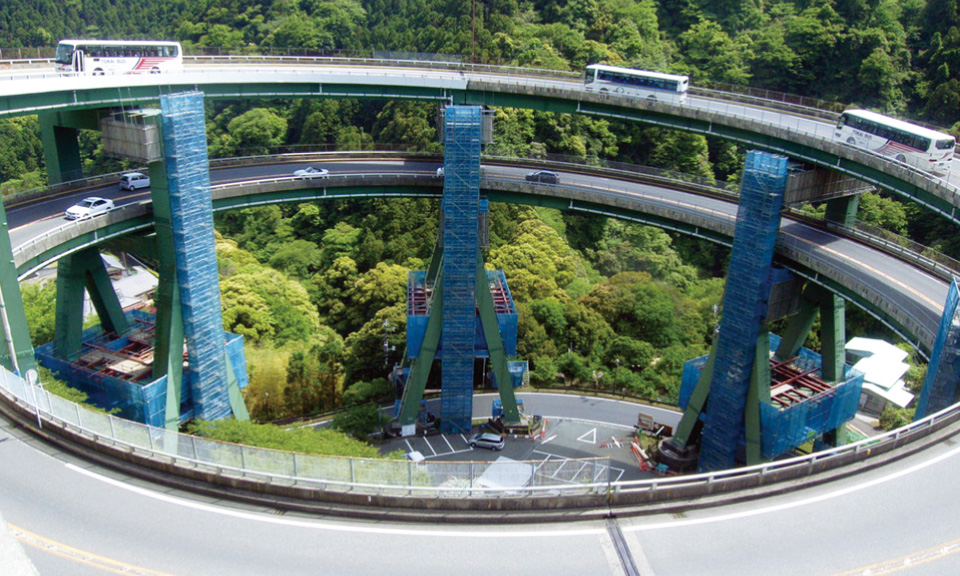

Sasanoda Bridge

Iwate

Client: Local government

Sasanoda Bridge is a loop bridge with a total length of 234 meters over National Route 343, which is designated as a reconstruction road for the Great East Japan Earthquake. The bridge piers are 60 meters high, and as part of the seismic strengthening work, carbon fiber was wound around the piers to reinforce them, and a bridge collapse prevention device was installed in the superstructure. We installed construction lifts to reduce theamount of labor required since the work involved moving along a height of 50 meters. The construction was completed without any accidents or mishaps, and received high praise from the client.(2020)

Metropolitan Expressway

Route No.6 Mukojima Line

Tokyo

Client: Expressway company

In the large-scale repair work on the Metropolitan Expressway Route No.6 Mukojima Line, we reinforced the bridge deck with carbon fiber and repaired fatigue cracks in the steel girders. We smoothly completed complicated construction adjustments with the riverside project (a large-scale project including the construction of a super embankment, large buildings, and landscape maintenance) adjacent to the construction area. The work was highly praised by the Metropolitan Expressway Co., Ltd and we received the President’s Commendation for Excellent Construction award.(2020)

Karakuwa Tunnel

Miyagi

Client: MLIT (National government)

The Karakuwa Tunnel is a 830m long tunnel located on National Route 45 in Kesennuma City, Miyagi Prefecture. We reinforced the inner surface of the tunnel with carbon fiber sheets. Road related consultations and other matters took time because the narrow width of the road meant the passage of large vehicles had to be restricted. However, we greatly shortened the time required for construction and safely completed the works, earning high praise from the MLIT’s Tohoku Regional Development Bureau, and we were awarded the Bureau Director’s Commendation for Excellent Construction.(2020)

National Route 165

Hakusan-ohashi Bridge

Mie

Client: Local government

Seismic strengthening, 2019

Nagoya Expressway No.3

Odaka Line

Aichi

Client: Expressway company

Life extention work, 2019

National Route 17

Tsukuba Footbridge

Saitama

Client: MLIT (National government)

Repair work, 2019

Aogishi Bridge

Wakayama

Client: Local government

Seismic strengthening, 2019

National Route 33

Niyodogawa-ohashi Bridge

Kochi

Client: MLIT (National government)

Seismic strengthening, 2019

Ochiai Bridge

Miyagi

Client: Local government

Seismic strengthening, 2019

Futase Bridge

Shizuoka

Client: Local government

Seismic strengthening, 2019

Arakawa River and

Nakagawa River truss bridge

Tokyo

Client: Railway company

Deterioration prevention, 2019

Kagamigawa-ohashi Bridge

Kochi

Client: MLIT (National government)

Seismic strengthening, 2019

Kachigawa Bridge

Aichi

Client: MLIT (National government)

Seismic strengthening, 2019

Toirigawa Bridge

Gunma

Client: Expressway company

Life extention work, 2019

Hanshin Expressway No.11

Ikeda Line

Osaka

Client: Expressway company

Life extention work, 2018

Otobaru Bridge

Oita

Client: Expressway company

Seismic strengthening, 2016

Nanadaru Loop Bridge

Shizuoka

Client: Local government

Seismic strengthening, 2015

Galleries

-

Kachidoki Bridge(Tokyo, 2017)

-

Kobe-ohashi Bridge(Hyogo, 2011)

-

Higashi-Kobe-ohashi Bridge(Hyogo, 2011)

-

Tohoku Shinkansen Pier(2011)

-

Tsumasa Bridge(Okinawa, 2008)

-

Fukuoka Airport(Fukuoka, 2007)

-

Osaka Castle(Osaka, 1996)

-

Kobe City Hall(Hyogo, 1996)

-

Nihonbashi Bridge(Tokyo, 1991)

-

Seikan Tunnel(Aomori – Hokkaido, 1987)

-

Namioka Hospital(Aomori, 1983)

-

Chashibetsu Bridge(Hokkaido, 1983)

-

Fujikawa Bridge(Shizuoka, 1966)

-

Showa-ohashi Bridge(Niigata, 1964)

Karisaka-Ohashi Bridge is located on National Highway 140, the only national highway connecting Saitama and Yamanashi Prefectures. As part of an earthquake reinforcement project for the emergency transportation road we replaced the bearings and installed displacement prevention devices. The work was carried out under difficult conditions, as it is a truss bridge located in a gorge, which made the transportation and installation of reinforcement parts challenging. Nevertheless, the project was completed with no accidents or incidents, and received high praise from the client.(2024)