In addition to complying with laws and regulations related to occupational health and safety, the SHO-BOND Group aims to create a comfortable work environment in which everyone strives to eliminate occupational accidents, while maintaining and improving their health, based on the philosophy that “respect for human life and safe construction take precedence over everything else.”

Health and safety management is one of the most important management issues of the Group. In recent years, our contract volume of large-scale construction projects has expanded, and our volume of complex construction projects such as expressways has been increasing. Completing these projects without any accidents demands a high level of safety skills along with a strong commitment to safety by everyone at the SHO-BOND Group and our partner companies.

Health and Safety Policy

Based on the philosophy that our highest priorities are the protection of life and the safety of construction activities, not only will the SHO-BOND Group comply with laws and regulations related to occupational health and safety but all of its officers and employees will also work to eliminate workplace accidents as well as make efforts to maintain and promote good health. What is more, we will further aim to create comfortable working environments.

- We will achieve a safety culture that is of an even higher level.

- We will establish a health and safety management system.

- We will ensure the steady implementation of risk assessments.

- We will carry out measures for the reduction of occupational accidents involving third parties and severe workplace accidents.

- We will execute thoroughgoing health and safety education toward our own employees and the staff of our partner companies.

- We will ensure thorough preventive measures for occupational diseases.

- We will promote work style reforms for the prevention of health disorders caused by overwork.

- We will thoroughly ensure the prevention of property damage accidents.

Health and Safety Management System

SHO-BOND has a health and safety management system in which everyone from the president to supervisors at all levels has clearly defined roles, responsibilities, and authority. This system is used to perform well-planned health and safety management operations at all business sites. We conduct health and safety patrols at construction sites to improve the level of health and safety.

Basic Responsibilities

| President | Determine the Group’s Health and Safety Policy and set health and safety targets | |

|---|---|---|

| General Managers of Regional Offices | Create annual health and safety management plans for SHO-BOND’s regional offices based on the Health and Safety Policy | |

| Branch Managers and Site Supervisors | Create and announce a construction health and safety policy, and set targets for construction health and safety | |

| Create, implement, review, and improve construction health and safety management plans | ||

| Partner Companies | Create risk assessment operating procedures | |

Health and Safety Patrols by the Company President

ISO45001 Certification

SHO-BOND CORPORATION and the KAKO-Group (construction subsidiaries) have received ISO45001 certifications.

Initiatives for Creating a SHO-BOND Culture of Safety

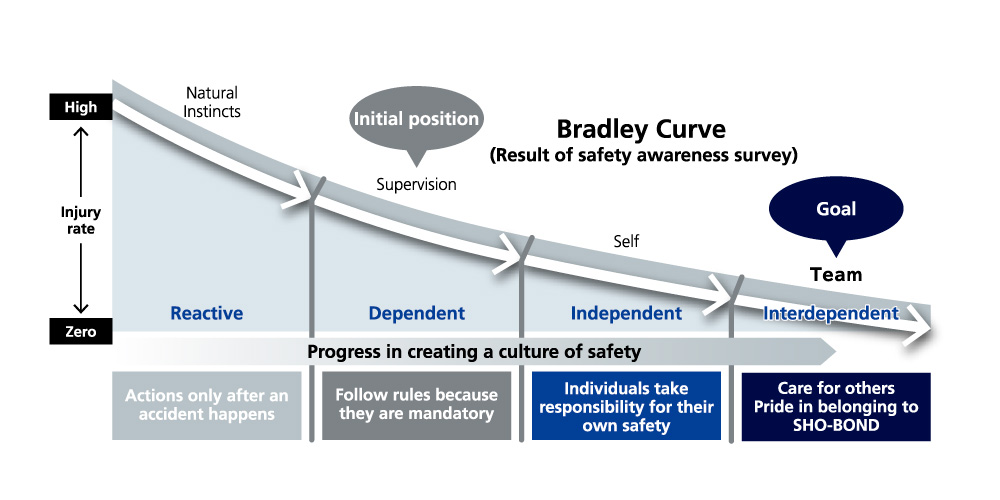

Our goal is to raise SHO-BOND’s safety culture from a “dependent” structure where supervisors oversee safety measures to an “independent” and “interdependent” structure in which individuals act independently and promote safety among themselves. We believe these changes will establish accident-free workplace environments where people can do their jobs with even greater safety and confidence. To accomplish these goals, we are promoting the Initiatives for Creating a SHO-BOND Culture of Safety.

Roadmap-based Training for SHO-BOND Employees and Partner Company Management

We are providing felt leadership training by external consultants to our Group employees and partner company management. This training aims to equip the trainees with the leadership skills to demonstrate their strong commitment to safety through action so that their improved awareness will spread to those around them, thus creating a comfortable workplace environment and organization, and fostering a culture of safety.

Somatosensory Health and Safety Education

at the Tsukuba Training Center

The Tsukuba Training Center has a full range of facilities for conducting effective health and safety education. To foster an awareness of health and safety, including risk perception, judgment criteria, and beliefs, we conduct employee training at the time of joining the company and when they are promoted to a higher level. In addition, we also provide hands-on education on health and safety to partner companies and overseas trainees, using actual training bridges and scaffolding, as well as VR and other hands-on equipment.

VR systems are used to generate realistic views of accidents

Training inside the scaffolding on the actual training bridge

Recreating Accidents with Mannequins

In the accident simulation area, actual accidents are reproduced using mannequins to show the potential causes of accidents and their severe consequences.

There is a training corner where employees can learn how to recognize unsafe locations and unsafe behavior on scaffolding. We also make it possible to intuitively learn about the dangers of disasters by checking unsafe situations in which accidents have occurred, such as accidents caused by vehicles for high lift work and accidents in which people injured their hands and feet while using a power tool.

Trial Dangle with a Torso Belt and Body Harness

Repairing and reinforcing bridges involves numerous tasks at elevated heights, such as erecting and dismantling scaffolding. For the sake of safety, it is inevitable to equip safety belts or harnesses for fall prevention. Therefore, ensuring everyone on-site using this safety equipment properly is essential for health and safety management. During training, participants are suspended by torso belts and body harnesses, so that they can tell the difference of the burden on their body, and learn how to help themselves relieve the burden they are taking by using a supplementary leg support attachment while waiting for help.

Simulating Falls with Mannequins

What would happen if people fell without wearing a safety belt or if the support rail for the harness hook was improperly placed? To demonstrate such accidents, we use mannequins weighing the same as typical workers. Experiencing the forceful shock firsthand, individuals learn to appreciate the gravity of occupational accidents and the importance of proper use of safety belts.