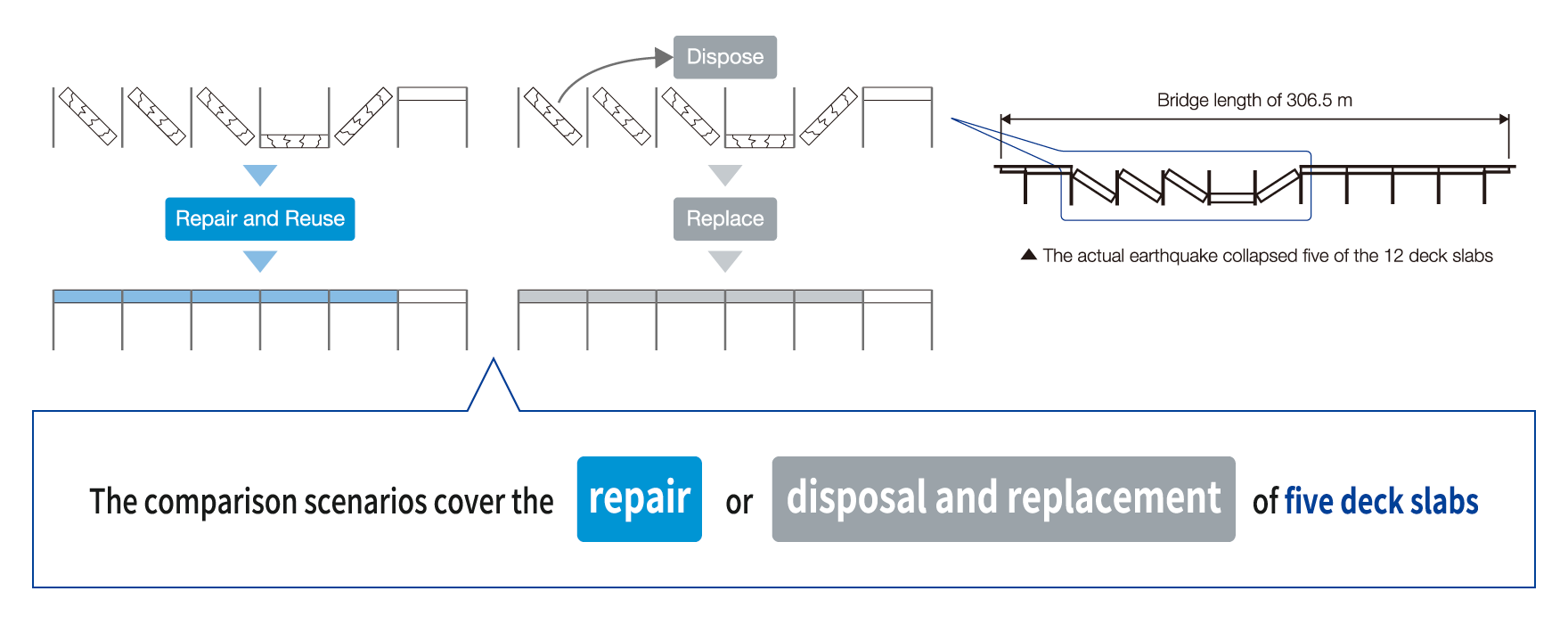

We have positioned “contribution to the development of sustainable cities” as one of our Materialities, and recognizing that a longer service life of infrastructure contributes to curbing CO2 emissions, we have formulated an action policy for mitigating climate change through our business in a way that leverages our strengths as an infrastructure maintenance specialist. In this feature, we take a look at the restoration of the Showa Ohashi Bridge, which was a project of significance to the Group, to check what effect the restoration work had on CO2 emissions. We have done this by estimating the CO2 emissions volumes generated by new materials and waste in a scenario where the earthquake-damaged deck slabs were repaired and a scenario where they were disposed of and replaced.

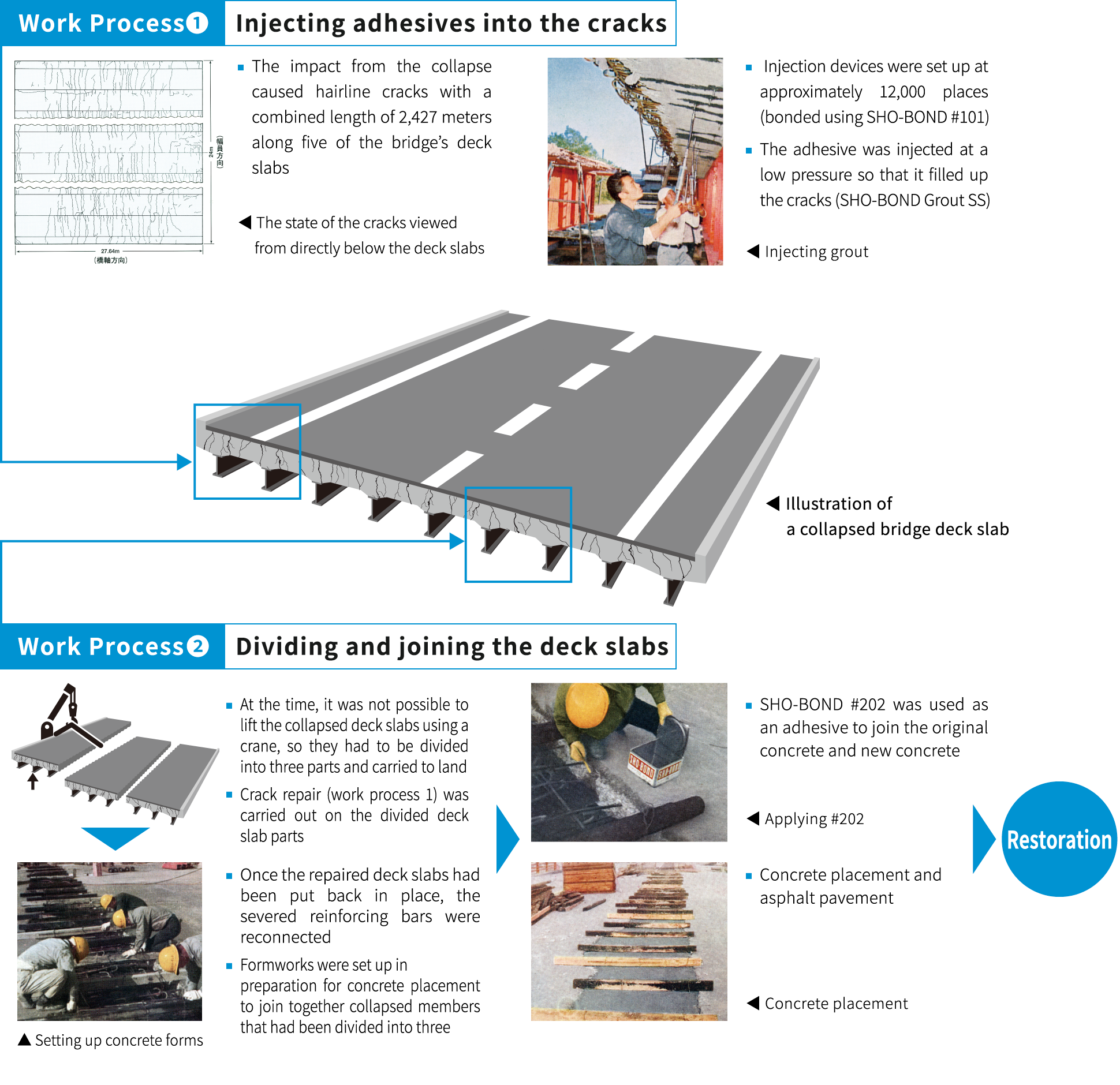

Overview of the Repair and Restoration Work

Materials and Waste Volumes – Estimate Assumptions

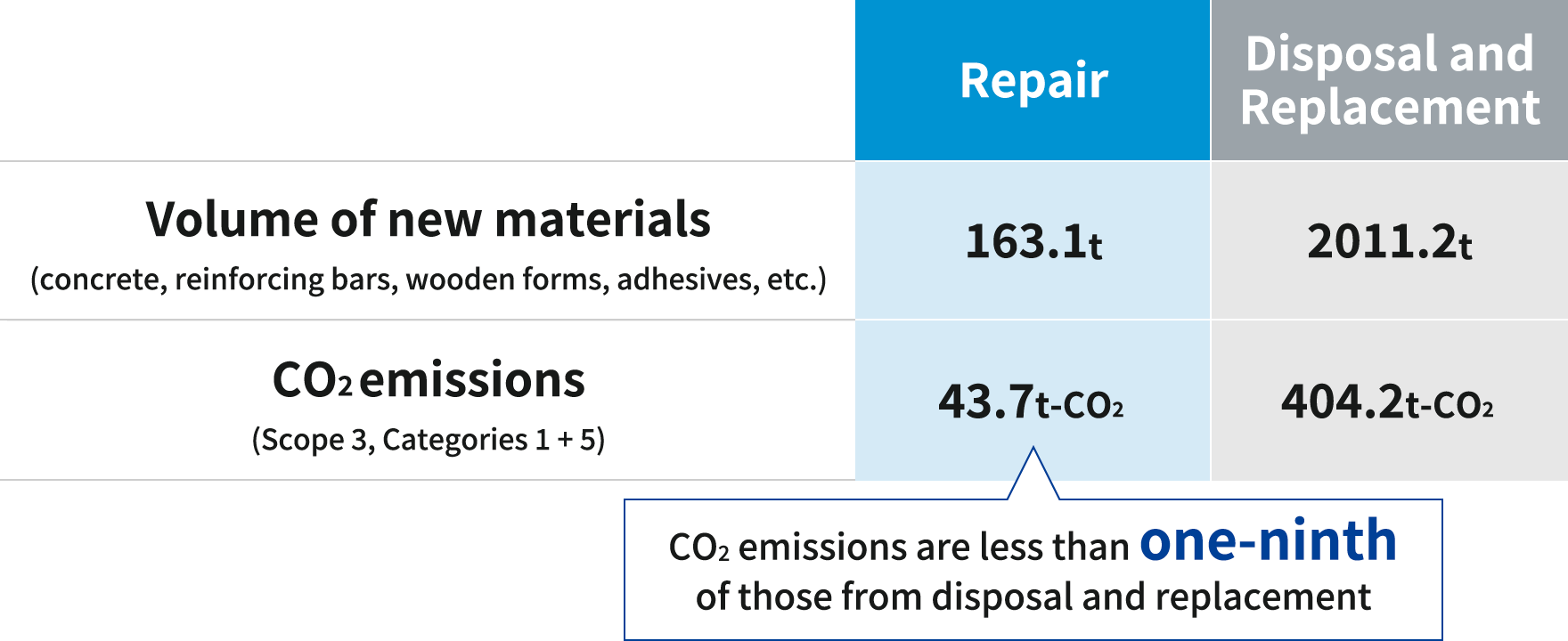

Comparison of CO2 Emissions

As you can see above, the estimates show that the CO₂ volume (Scope 3) generated by new materials and waste in the disposal and replacement scenario was over 9 times higher than in the scenario where the five deck slabs were repaired. When considering actual construction, in addition to CO₂ emissions from new materials and waste (Scope 3), you also need to factor in Scope 1 and Scope 2 emissions from sources such as construction machinery, heavy machinery, and various transportation vehicles, and it is estimated that this will make the difference even greater.

We will continue to contribute to mitigating climate change through our main business of repair and reinforcement construction.

Notes about the Estimates

- The estimates do not take the bridge beams (steel frame) into consideration.

- The size of the deck slabs was: a total width of 24.8m, slab width (road and pavement) of 24m, beam length of 27.54m, slab thickness of 18cm, and paving thickness of 5cm (based on documents from the time).

- For the replacement scenario, the volume of main new materials was 1,516 tons of concrete, 380 tons of asphalt paving, 97 tons of reinforcing bars, and 18 tons of wooden formworks.

- For the repair scenario, the volume of main new materials was 117 tons of concrete, 35 tons of asphalt paving, 9 tons of reinforcing bars, 2 tons of wooden formworks, and 1 ton of adhesive materials.

- For the replacement scenario, the volume of waste was estimated as the volume of the replaced deck slabs.

- The estimates do not include the materials’ packaging, etc.

- The volume of reinforcing bars, etc., found in the deck slabs has been estimated using specifications from 1964.

- In order to make a fair comparison with repair work carried out in 1964, the volume of materials used for new construction has been estimated based on construction methods used at the time.

- The CO2 emission factors used in the estimates are derived from the databases of the Ministry of the Environment and various other sources.

- Emissions from the processes of recovering and reinstalling the collapsed deck slabs are deemed to be roughly equal for both scenarios and have therefore been omitted from the estimates.